Confidential Client Oceanside SUT & Spine

Located in Oceanside, California, this six-building, 500,000-square-foot biopharmaceutical manufacturing campus marks a new era in biotech production. Purpose-built for the small batch biologics sector, the facility leverages advanced manufacturing technologies and modular process equipment to deliver speed, flexibility, and innovation in commercial medicine production.

Project Details

Project Owner:

Contractor:

Structural Engineer:

Architect:

Steel Tonnage:

860 tons

Location:

Oceanside, CA

Schuff Services: Project Management, Steel Detailing, Steel Fabrication, Steel Erection, BRB

Project Overview

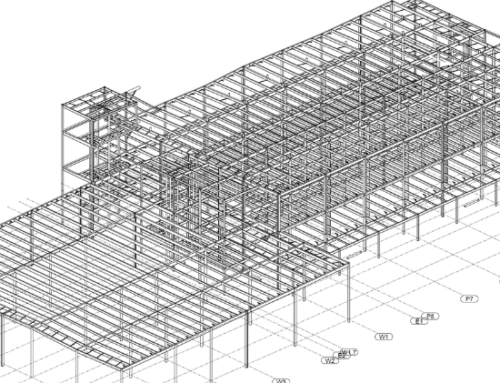

The campus includes a steel-framed, three-story manufacturing building with 26-foot floor heights, supported by a central utility “spine” that serves all six main structures. Additional buildings include a laboratory and office facility, warehouse, central plant, and operations and maintenance facilities. The site also features essential infrastructure such as hazardous waste storage, a pump house, fire water storage, and a wastewater treatment plant.

More than 70% of the process systems were modularized and factory-tested prior to installation, minimizing on-site technical issues and enabling process and building work to proceed in parallel. This modular strategy not only reduced trade stacking but also dramatically accelerated the construction and validation timeline.

Schuff Steel fabricated and erected 860 tons of structural steel for the project, including the installation of Buckling-Restrained Braces (BRBs) to improve seismic resilience. When wind girt clips presented tolerance challenges, Schuff Steel swiftly expedited materials, fabrication, and erection to resolve the issue—demonstrating flexibility, precision, and commitment to excellence under pressure.

Constructed over 2.5 years and a capital investment of $380 million, the campus was delivered on time and under budget. The end result exceeded the owner’s expectations, reinforcing the value of collaboration and innovation in project delivery.

Let’s talk about

your next project

Confidential Client Oceanside SUT & Spine

Project Details

Project Owner:

Contractor:

Structural Engineer:

Architect:

Steel Tonnage:

860 tons

Location:

Oceanside, CA

Schuff Services: Project Management, Steel Detailing, Steel Fabrication, Steel Erection, BRB

Located in Oceanside, California, this six-building, 500,000-square-foot biopharmaceutical manufacturing campus marks a new era in biotech production. Purpose-built for the small batch biologics sector, the facility leverages advanced manufacturing technologies and modular process equipment to deliver speed, flexibility, and innovation in commercial medicine production.

The campus includes a steel-framed, three-story manufacturing building with 26-foot floor heights, supported by a central utility “spine” that serves all six main structures. Additional buildings include a laboratory and office facility, warehouse, central plant, and operations and maintenance facilities. The site also features essential infrastructure such as hazardous waste storage, a pump house, fire water storage, and a wastewater treatment plant.

More than 70% of the process systems were modularized and factory-tested prior to installation, minimizing on-site technical issues and enabling process and building work to proceed in parallel. This modular strategy not only reduced trade stacking but also dramatically accelerated the construction and validation timeline.

Schuff Steel fabricated and erected 860 tons of structural steel for the project, including the installation of Buckling-Restrained Braces (BRBs) to improve seismic resilience. When wind girt clips presented tolerance challenges, Schuff Steel swiftly expedited materials, fabrication, and erection to resolve the issue—demonstrating flexibility, precision, and commitment to excellence under pressure.

Constructed over 2.5 years and a capital investment of $380 million, the campus was delivered on time and under budget. The end result exceeded the owner’s expectations, reinforcing the value of collaboration and innovation in project delivery.